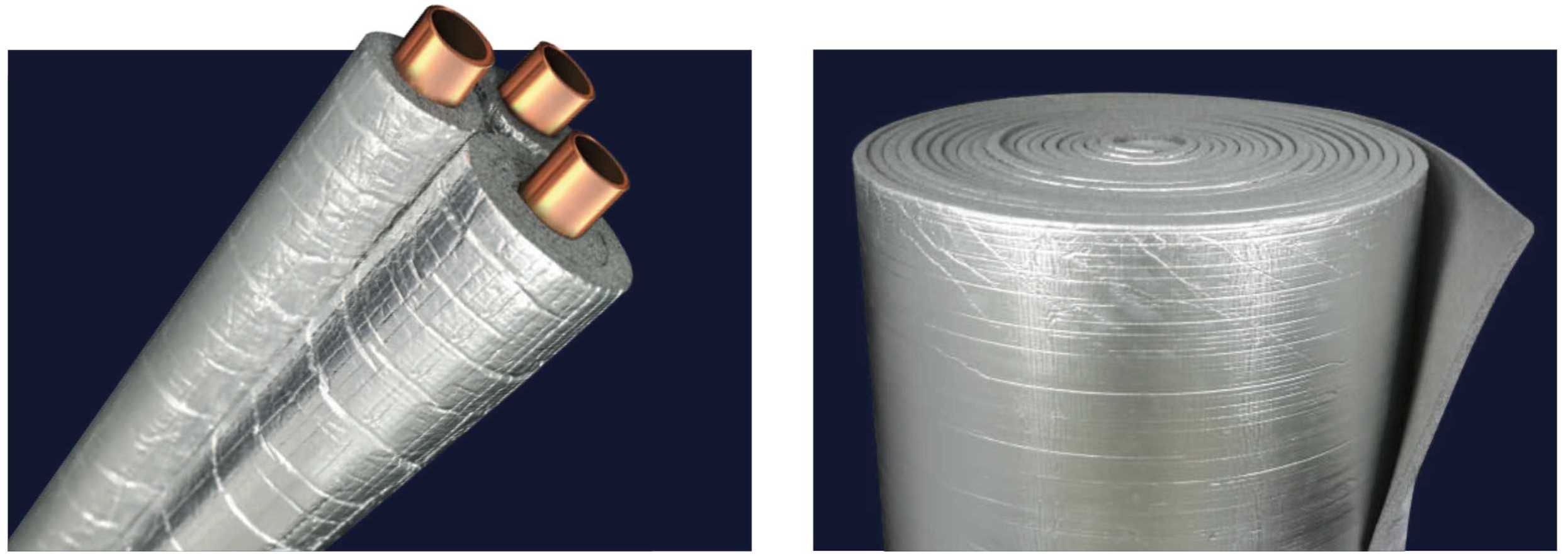

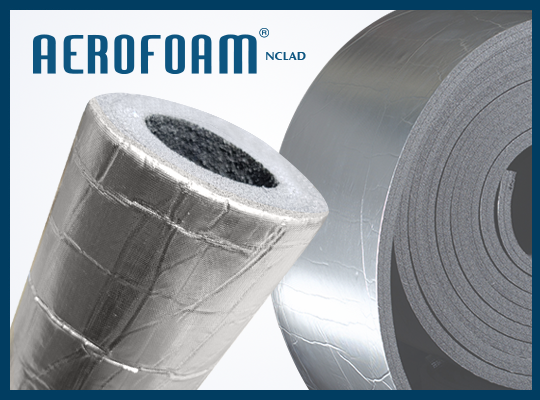

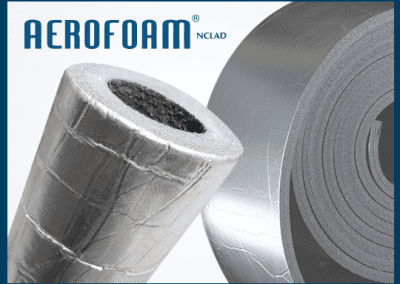

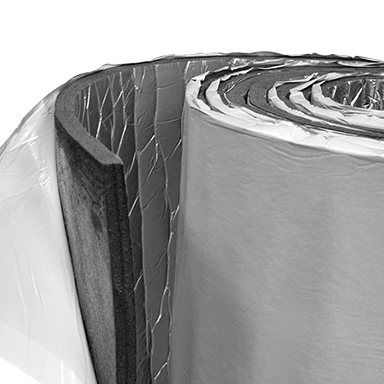

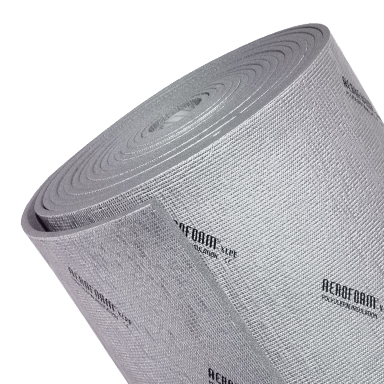

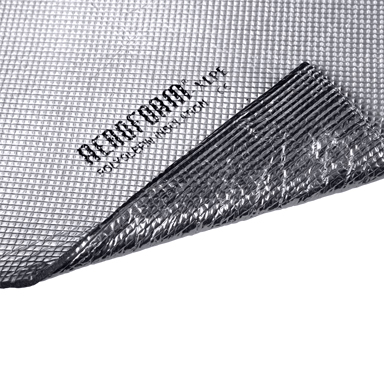

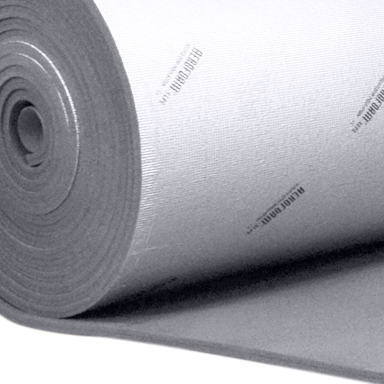

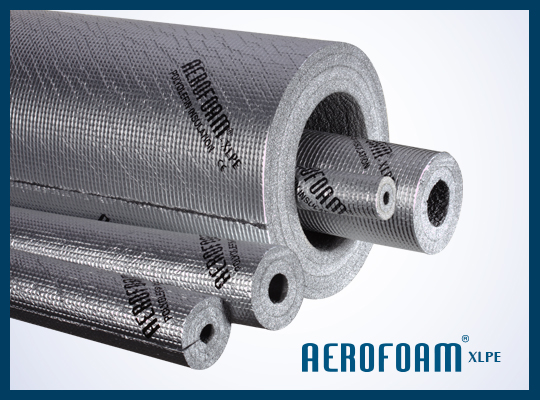

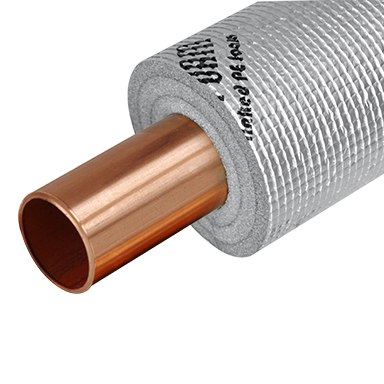

Aerofoam® Polyolefin Thermal Insulation N Clad system contains rolls, sheets, tubes and tapes. The thermal insulation foam is made of closed cell cross linked polyolefin coated with a strong and durable jacketing which replaces costly and complex aluminum, zinc plated steel or stainless-steel sheet facings. The foam has excellent properties in terms of condensation control, mechanical and chemical resistance, long term thermal block and sound absorption.

Aerofoam® Polyolefin Thermal Insulation N Clad rolls, sheets, tubes and tapes have a very good dimensional stability, showing a “memory effect” (they tend to come to their original shape after being compressed).

Aerofoam® Polyolefin N Clad sheets, rolls, tubes and tapes are an economical solution compared to the expensive and labor-intensive aluminum, zinc plated steel or stainless-steel cladding. Some of the benefits are the following: less skilled labor required, quick installation (50% faster than metal cladding), light weight material , safe to use (N Clad jacketing – no safety equipment required), easy to cut, no drill required (light punching tool is enough), no power tools required, easy and light to lift and carry, N Clad jackets can be cut on-site without waste (on a cutting table) and space-saving storage.