by aero_admin | Jun 1, 2022

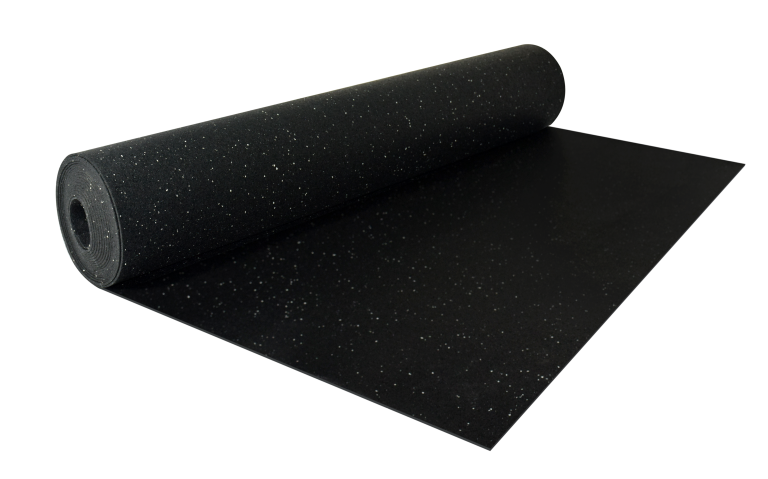

AeroSound® RSF is a flooring system designed to reduce impact sound. It is made of elastomeric rubber with recycled rubber content. High acoustic, mechanical, and thermal performance is provided by the rubber structure. Separating a concrete slab from the screed or final finish is a commonly used application. It can also be installed directly under ceramic tiles with cement-based glue due to its great density and durability. AeroSound® RSF can be used for heavy machine foundations to isolate it from the structure of the building, preventing structural vibration and noise transfer. AeroSound® RSF is apt for installation in civil and industrial applications.

by aero_admin | Mar 12, 2017

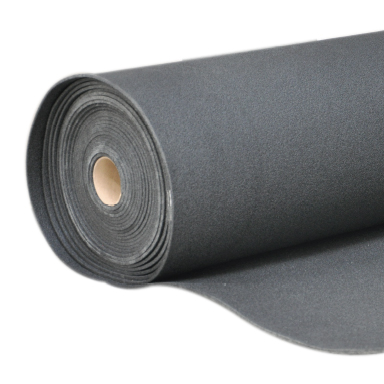

AeroSound® Acoustic Silent Floor is designed to reduce impact of sound in floating floor systems. It has been designed for use in both commercial and residential buildings

Aerofoam® Acoustic Silent Floor is a flexible cross linked closed cell polyolefin foam with good quality and medium density underlay for all floating floor applications. Acoustic Silent Floor is designed to reduce impact of sound in floating floor systems. Designed for use in both commercial and residential buildings, such as apartments, hotels, hospitals, schools and universities to reduce the sound transmission level to the floors below. Usual application is to separate concrete base floor from final screed or screed from final finishing. It is used in corners (between wall and floor) for this same reason.

by aero_admin | Mar 12, 2017

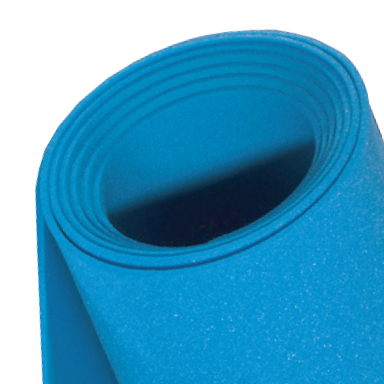

AeroSound® Acoustic duct liner has a semi open cell structure which is suitable for thermal insulation solutions and sound absorption, mainly inside the ducts.

Aerofoam® Acoustic Liner is a flexible cross-linked semi open cell polyolefin foam with or without pressure sensitive adhesive on one side. Acoustic Duct Liner is designed to reduce the sound pressure level inside air ducts, but it can be successfully used in operating cabins, silencers, decompression boxes and all kinds of casing. Aerofoam® sound duct liner is free of harmful irritants making it safe to handle and install.

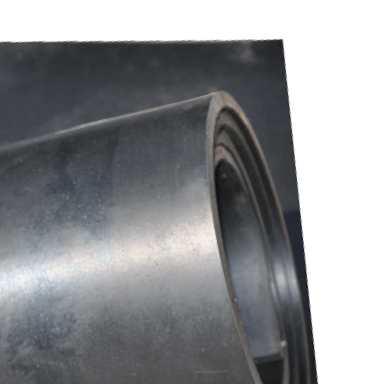

by aero_admin | Mar 12, 2017

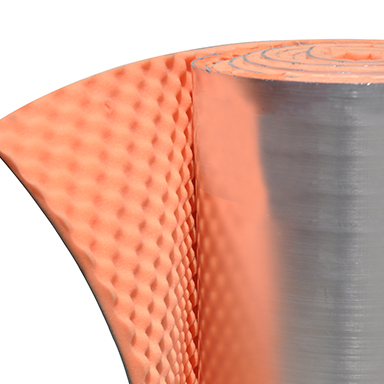

Product can be an excellent sound barrier as it is, or as an additional layer on existing partition.

AeroSound® Acoustic Elastomeric Sound Lagging be used as a single product or in combination with other Aerofoam® products. It’s a semi-open cell elastomeric thermal insulation foam covered with solid high mass rubber or MLV wherein both the layers are integrated during production process. The product has been designed to reduce sound propagation coming from various sources and can be an excellent sound barrier as it is, or as an additional layer on existing partition. Can be used as a single product or in combination with other Aerofoam® thermal insulation solutions products.

Moreover, the product Aerofoam® Acoustic Thermal Insulation can be used when thermal and acoustic insulation are required at the same time PU open cell foam can be used as a product variant. Examples of applications: covering waste water or drainage pipes, garbage pipes, walls and kind of partition, ventilation fan covering, compressors units covering, engine compartments, air duct sound insulation (outside).

by aero_admin | Mar 12, 2017

ACOUSTIC COMFORT

During the construction of a home or an office, we focus our attention to the appropriate standard of the building, air conditioning, proper ventilation, orientation towards cardinal points of the compass, sun exposure or the distance from noise sources, such as busy roads. But we often forget about the thing that is imperceptible – the acoustic comfort thermal insulation solutions. The sounds of ventilation, sanitation, equipment such as lifts and compressors, and of course the sounds generated by our neighbors or even precipitation – all this can cause noise disruption.

Providing adequate acoustic comfort insulation has a substantial impact on our well-being at home as well as efficiency and concentration at work. The most effective solution is to ensure sound isolation of each room at the stage of construction of the building and use of sound absorptive materials. However, thanks to modern technology, it is possible to increase the acoustic comfort even in projects that have already been completed.